Unraveling Rubber: The Science Behind Durable Rubber Bands

Time : Dec 05, 2025 View : 116

Ever snapped a rubber band and watched it bounce back? It’s simple, yet amazing. But what keeps these everyday items from breaking down after just a few uses? The science behind durable rubber bands dives into materials, processes, and real-world demands. Whether you’re tying up packages, organizing office supplies, or using them in creative ways, understanding this can change how you pick and use them. This post breaks it down for folks like you—busy professionals, hobbyists, or just curious minds—who want reliable tools that last.

Durable rubber bands aren’t just stretchy loops. They stand up to pulls, twists, and time. We’ll explore the core ideas, from raw stuff to final tests. Along the way, see how this knowledge boosts your choices and even builds stronger brands in business or personal projects.

The Building Blocks of Rubber Bands

Rubber bands start with basic elements that give them their snap. But durability? That’s where science steps in.

Natural vs. Synthetic: Picking the Right Base

Natural rubber comes from tree sap, latex from hevea trees. It’s flexible and springs back well. Yet, it can crack under heat or light. That’s why makers blend in synthetics. These man-made versions resist wear better. Think about a band that holds tight in hot warehouses or cold storage. Mixing both creates bands that stretch far without snapping.

Synthetics like polyisoprene mimic nature but add strength. They fight off oils and chemicals too. For you, this means bands that work in kitchens, labs, or outdoors. No more quick breaks.

Key Properties That Drive Durability

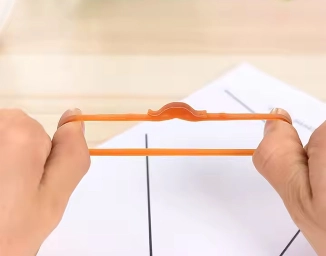

What makes a band tough? Elasticity tops the list. It measures how far it stretches and returns. High elasticity means it can extend seven times its length—impressive, right?

Then there’s tensile strength. This fights breaks under pull. Bands with high tensile hold heavy loads. Wear resistance keeps them from fraying. Anti-aging factors block cracks from time or air.

-

Elasticity: Bounce back after stretch.

-

Tensile Strength: Handle force without snap.

-

Wear Resistance: Last through rubs and twists.

-

Anti-Aging: Stay strong over months.

These traits come from careful material picks. Natural rubber shines in bounce, while additives boost the rest. Result? Bands that serve you longer, cutting waste.

How Makers Craft Lasting Bands

Turning raw materials into durable bands takes skill. It’s not just mixing and shaping. Science guides each step to build in strength.

The Raw Material Prep Stage

It begins with harvesting or making the base. Natural latex gets cleaned and concentrated. Synthetics form in labs through reactions. Blends happen here—adding sulfur for vulcanization. This process links molecules, making rubber tougher. Without it, bands would melt or stick.

Heat and pressure cure the mix. Imagine dough turning into bread. Here, soft goo becomes firm yet flexible. Additives like antioxidants shield against breakdown. UV protectors guard from sun. For you, this means bands that don’t fade or weaken fast.

Shaping and Cutting for Precision

Once cured, the rubber forms tubes or sheets. Machines extrude them into long strands. Then, slicing creates individual bands. Thickness matters—a thin one for light ties, thicker for heavy duties.

Quality checks happen throughout. Pull tests stretch samples to limits. If they snap too soon, tweaks follow. This ensures every batch meets standards. In business, such bands build trust. Customers return when products hold up.

Testing: The Ultimate Proof

No band ships without rigorous checks. Labs simulate real use. Bands get stretched thousands of times. Heat ovens test endurance. Cold chambers check brittleness.

A simple table shows common tests:

| Test Type | What It Checks | Why It Matters |

|---|---|---|

| Stretch Cycle | Repeated pulls | Simulates daily use |

| Heat Exposure | High temperatures | Prevents melting in storage |

| UV Aging | Sunlight simulation | Keeps bands from cracking outdoors |

| Chemical Dip | Oil or solvent contact | Ensures resistance in workshops |

These steps catch weak spots early. For brands, it means fewer returns. You get peace of mind knowing your bands won’t fail mid-task.

Why Durability Wins in Real Life

Durable bands do more than last. They save time and money. Think about it. Cheap ones break, forcing replacements. Strong ones keep going.

In offices, they organize files without snapping. At home, they secure bundles. Industries rely on them for packaging veggies or parts. Durability cuts downtime. For personal brands—like a crafter selling handmade goods—using tough bands shows quality. It tells customers you care about details.

Businesses gain too. Reliable suppliers mean steady supply chains. No delays from faulty ties. This builds reputations. Customers associate your name with dependability. It’s subtle, but powerful.

Short term? Bands hold. Long term? They foster loyalty. Pick durable, and watch efficiency rise.

Pushing Boundaries: New Twists in Rubber Science

Science doesn’t stop. Innovations keep bands evolving.

Researchers tweak molecules for better stretch. Nano-additives make them lighter yet stronger. Eco-friendly options use recycled materials. These cut environmental harm without losing toughness.

Biodegradable bands break down naturally. Yet, they match traditional durability. For green-minded users, this fits. Imagine bands that last your project, then vanish harmlessly.

Smart bands? Some embed sensors for tracking stretch. Useful in labs or fitness. But core science remains—balancing flexibility with strength.

These advances elevate brands. Companies adopting them stand out as forward-thinkers. You, as a user, get tools that adapt to modern needs.

Meet the Experts: Zhejiang VIET-Y Rubber Products Co., Ltd.

Looking for a reliable source in this field? Zhejiang VIET-Y Rubber Products Co., Ltd. stands out as a key supplier of rubber band series products. Based in Yiwu City, they’ve built a solid name since 2010. They focus on high-quality bands across lines like RUBBER SERIES for everyday ties, TPU SERIES for hair accessories and flexible uses, TPR SERIES for colorful decorative options, and LATEX SERIES for strong industrial needs.

Their approach? Quality first, with natural materials from trusted sources. They blend tradition with modern methods to deliver bands that stretch far and hold strong. Whether you’re stocking for business or personal projects, their range covers global demands. With a push on customer satisfaction, they offer custom services too. It’s about connecting needs with elastic solutions that last.

Conclusion

Wrapping up, the science behind durable rubber bands blends materials, crafting, and testing into everyday heroes. From natural bounce to synthetic toughness, these elements create bands that endure. They boost efficiency, cut waste, and build trust—key for personal and business brands. Next time you reach for one, remember the hidden smarts making it reliable. Ready to dive deeper? Check the FAQs below for quick insights.

FAQs

What is the main science behind durable rubber bands?

The science behind durable rubber bands centers on vulcanization, where heat and additives link molecules for better strength and elasticity. This process turns soft rubber into tough bands that resist breaks and aging.

How do materials affect the durability of rubber bands?

Materials play a big role in the science behind durable rubber bands. Natural rubber gives great stretch, while synthetics add resistance to heat, chemicals, and wear—ensuring they last in tough spots.

Can environmental factors impact rubber band durability?

Yes, things like sunlight and humidity can weaken bands over time. The science behind durable rubber bands includes UV protectors and anti-aging additives to fight these, keeping them strong longer.

Why choose high-quality rubber bands for business use?

In business, the science behind durable rubber bands means fewer failures and more reliability. They support smooth operations, from packaging to organizing, helping build a solid brand image.

How has innovation changed the science behind durable rubber bands?

Innovation brings eco-friendly options and stronger blends. The science behind durable rubber bands now includes biodegradable materials that maintain toughness, appealing to green-focused users and brands.

Latest News

-

Feb. 26, 2026WHY RUBBER BANDS ARE SO IMPORTANT NOWDiscover why rubber bands are essential for office organization, productivity, and cost-effective administrative solutions.

-

Feb. 19, 2026The Safety and Compliance of TPU Elastics in Food Contact and Hygiene ApplicationsDiscover the safety and compliance of TPU elastics for food packaging and hygiene applications, ensuring durability and reliability.

-

Feb. 12, 2026Can TPU Rubber Bands Be Used in Medical or Health-Related ProductsTPU bands, medical products, compression garments, prosthetics, healthcare applications